Services

Supervision of the Vessel Dry Dock and Shipyard Repair

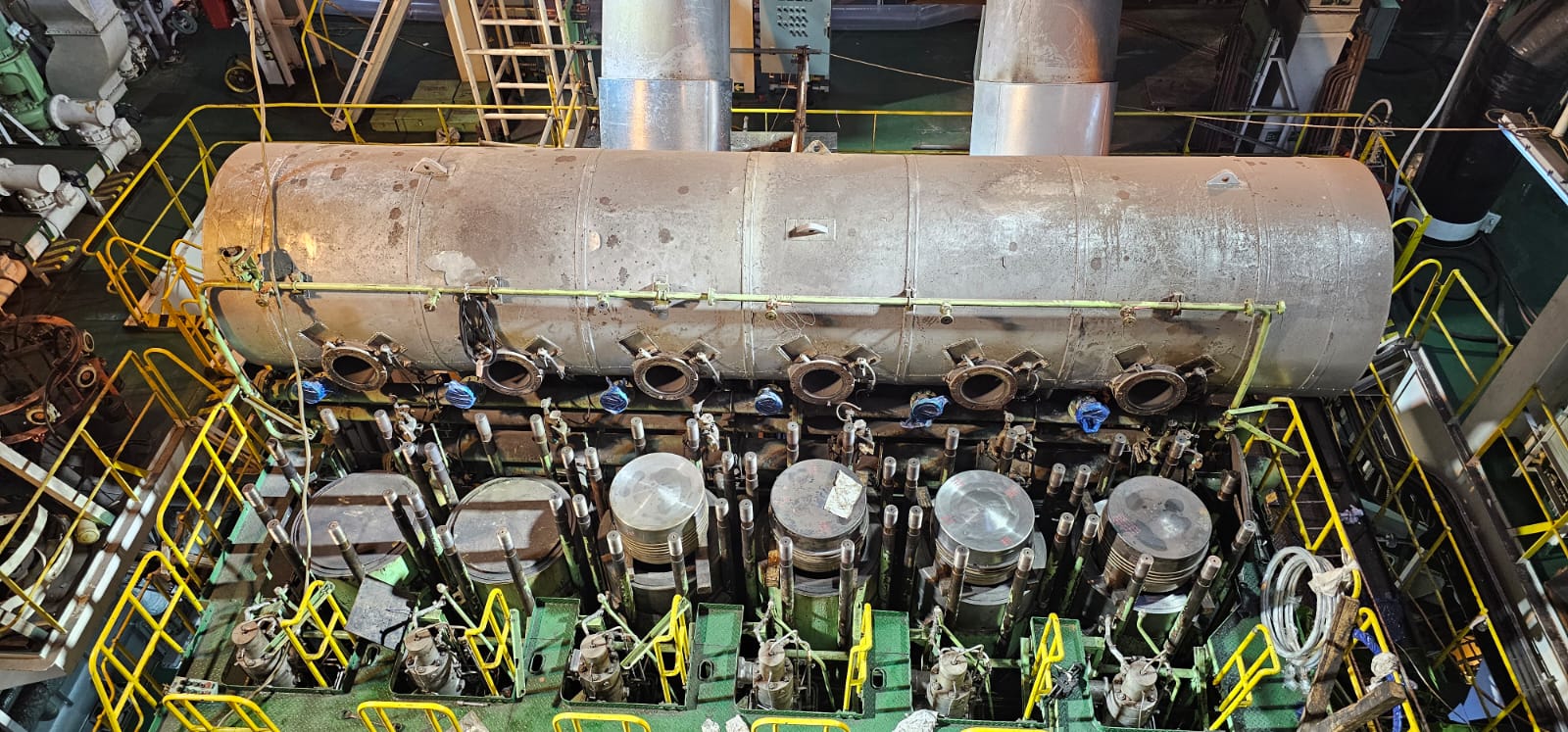

Supervision of dry docking and shipyard repairs ensures the vessel is maintained to the highest standards, ensuring safety, compliance, and operational efficiency. The process begins with pre-docking planning, including inspections, repair scope definition, and budget approval.

The supervisor oversees all activities, including hull cleaning, painting, propeller and rudder inspections, and machinery repairs. They ensure compliance with class society rules, flag state regulations, and safety protocols. Regular progress reports are provided to stakeholders, and any deviations from the plan are addressed promptly.

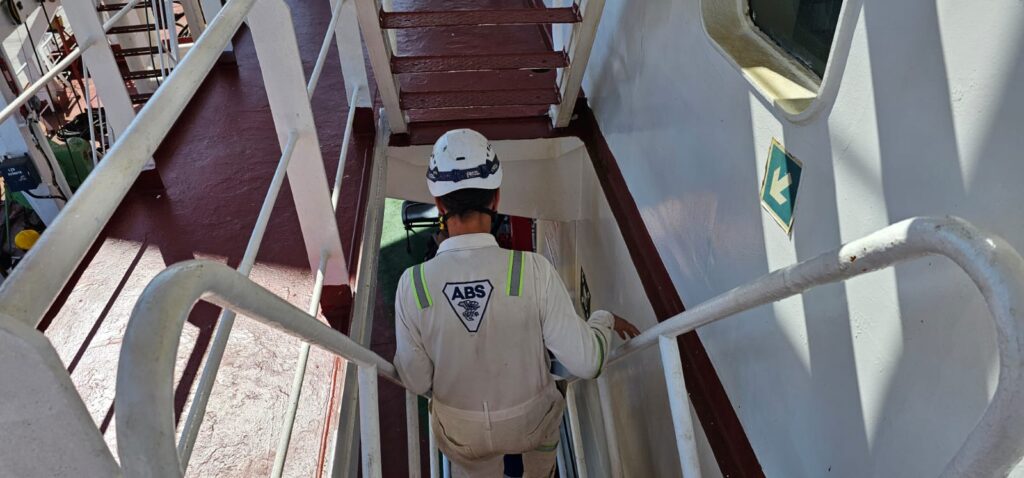

Coordination with the Shipyard, Contractors and Class Surveyors

Key tasks include monitoring contractor performance, verifying repair quality, and ensuring timely completion. The supervisor also coordinates with classification surveyors for necessary certifications. Post-repair, sea trials are conducted to verify the vessel’s performance before it returns to service.

Effective supervision minimizes downtime, reduces costs, and ensures the vessel’s longevity and compliance with international standards. It requires expertise in ship systems, repair techniques, and project management to deliver a seamless dry docking experience

Coordination with the Service Providers and On-Site Recovery Engineers

Effective coordination with service providers and on-site recovery engineers ensures seamless execution of vessel repairs and maintenance. This involves clear communication of repair scopes, timelines, and safety protocols. The coordinator acts as the primary point of contact, facilitating collaboration between shipowners, shipyards, and contractors. They monitor progress, resolve issues, and ensure compliance with technical specifications and regulatory standards. Regular updates are provided to stakeholders, and any deviations are addressed promptly. By maintaining strong relationships and ensuring efficient workflows, the coordinator minimizes downtime, optimizes costs, and ensures the vessel’s timely return to service.

Spare Parts supply

Efficient spare parts supply ensures minimal vessel downtime and smooth operations. The process involves identifying required parts, sourcing from reliable suppliers, and managing inventory to prevent shortages. Key steps include:

**Identification:** Determine parts needed for maintenance or repairs.

**Procurement:** Source high-quality, cost-effective components.

**Logistics:** Arrange timely delivery to the vessel or shipyard.

**Inventory Management:** Maintain optimal stock levels to avoid delays.

Effective coordination with suppliers and stakeholders ensures compliance with technical specifications and regulatory standards.

Technical Services arangements

Our expert team provides comprehensive technical services onboard your vessel, ensuring optimal performance and full compliance with **Class requirements**. From routine maintenance and emergency repairs to system upgrades and performance optimization, we deliver tailored solutions to minimize downtime and maximize efficiency. Our services include engine diagnostics, electrical systems troubleshooting, hull inspections, and advanced welding—all performed in strict adherence to industry standards. With 24/7 support and a commitment to safety, sustainability, and regulatory compliance, we keep your vessel operating smoothly. Trust us for reliable, cost-effective, and high-quality technical solutions tailored to your needs.

**Contact us today to schedule your onboard service!**